|

Process Cycle |

Equipment |

Tooling |

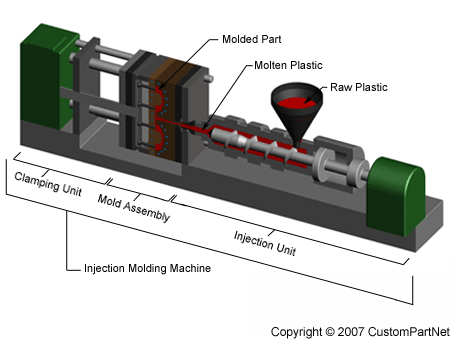

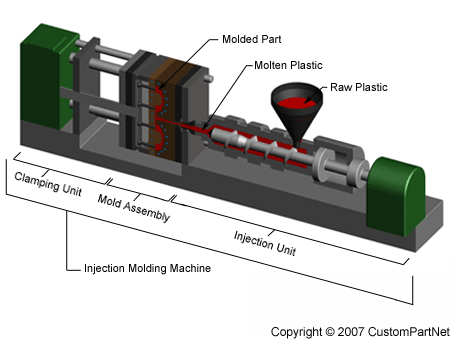

Injection molding is the most commonly used manufacturing process for the fabrication of plastic parts. A wide variety of products are manufactured using injection molding, which vary greatly in their size, complexity, and application. The injection molding process requires the use of an injection molding machine, raw plastic material, and a mold. The plastic is melted in the injection molding machine and then injected into the mold, where it cools and solidifies into the final part. The steps in this process are described in greater detail in the next section.

Injection molding is used to produce thin-walled plastic parts for a wide variety of applications, one of the most common being plastic housings. Plastic housing is a thin-walled enclosure, often requiring many ribs and bosses on the interior. These housings are used in a variety of products including household appliances, consumer electronics, power tools, and as automotive dashboards. Other common thin-walled products include different types of open containers, such as buckets. Injection molding is also used to produce several everyday items such as toothbrushes or small plastic toys. Many medical devices, including valves and syringes, are manufactured using injection molding as well.

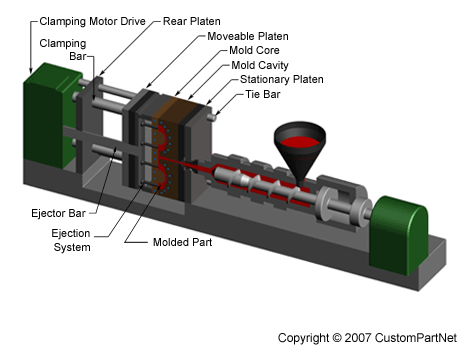

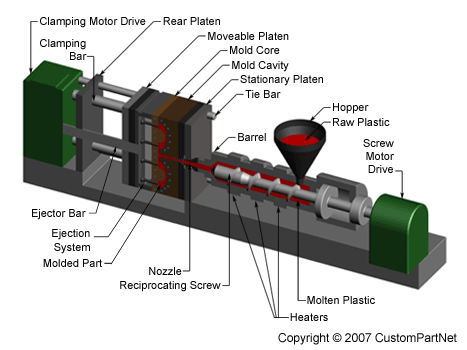

Injection molding overview

Injection molding overview

The process cycle for injection molding is very short, typically between 2 seconds and 2 minutes, and consists of the following four stages:

- Clamping - The two mold halves are securely closed

- Injection - The raw plastic is melted and injected into the mold

- Cooling - The molten plastic solidifies into the shape of the part

- Ejection - The mold halves separate and the part is ejected

Injection molding overview

Injection molding overview

Prior to the injection of the material into the mold, the two halves of the mold must first be securely closed by the clamping unit. Each half of the mold is attached to the injection molding machine and one half is allowed to slide. The hydraulically powered clamping unit pushes the mold halves together and exerts sufficient force to keep the mold securely closed while the material is injected. The time required to close and clamp the mold is dependent upon the machine - larger machines (those with greater clamping forces) will require more time. This time can be estimated from the dry cycle time of the machine.

Injection molding clamping

Injection molding clamping

The raw plastic material, usually in the form of pellets, is fed into the injection molding machine, and advanced towards the mold by the injection unit. During this process, the material is melted by heat and pressure. The molten plastic is then injected into the mold very quickly and the buildup of pressure packs and holds the material. The amount of material that is injected is referred to as the shot. The injection time is difficult to calculate accurately due to the complex and changing flow of the molten plastic into the mold. However, the injection time can be estimated by the shot volume, injection pressure, and injection power.

Injection molding injection

Injection molding injection

The molten plastic that is inside the mold begins to cool as soon as it makes contact with the interior mold surfaces. As the plastic cools, it will solidify into the shape of the desired part. However, during cooling some shrinkage of the part may occur. The packing of material in the injection stage allows additional material to flow into the mold and reduce the amount of visible shrinkage. The mold can not be opened until the required cooling time has elapsed. The cooling time can be estimated from several thermodynamic properties of the plastic and the maximum wall thickness of the part.

After sufficient time has passed, the cooled part may be ejected from the mold by the ejection system, which is attached to the rear half of the mold. When the mold is opened, a mechanism is used to push the part out of the mold. Force must be applied to eject the part because during cooling the part shrinks and adheres to the mold. In order to facilitate the ejection of the part, a mold release agent can be sprayed onto the surfaces of the mold cavity prior to injection of the material. The time that is required to open the mold and eject the part can be estimated from the dry cycle time of the machine and should include time for the part to fall free of the mold. Once the part is ejected, the mold can be clamped shut for the next shot to be injected.

Injection molding ejection

Injection molding ejection

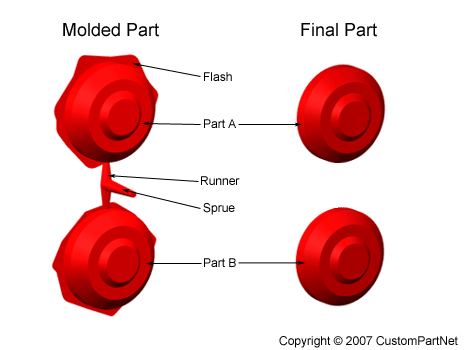

After the injection molding cycle, some post processing is typically required. During cooling, the material in the channels of the mold will solidify attached to the part. This excess material, along with any flash that has occurred, must be trimmed from the part, typically by using cutters. For some types of material, such as thermoplastics, the scrap material that results from this trimming can be recycled by being placed into a plastic grinder, also called regrind machines or granulators, which regrinds the scrap material into pellets. Due to some degradation of the material properties, the regrind must be mixed with raw material in the proper regrind ratio to be reused in the injection molding process.

Injection molding cycle

Injection molding cycle

- Soda bottle

- Bicycle handle grip

- Remote control cover

- Solid toy ball

- 1 second

- 30 seconds

- 3 minutes

- 6 minutes

- Injection, Cooling, Clamping, Ejection

- Injection, Clamping, Cooling, Ejection

- Clamping, Cooling, Injection, Ejection

- Clamping, Injection, Cooling, Ejection

- The front mold half is pushed towards the rear mold half

- The rear mold half is pushed towards the front mold half

- Both mold halves are pushed towards each other

- The mold is one piece and is clamped in place

- Molten plastic is poured into the machine

- Solid plastic pellets are poured into the machine

- Solid plastic sheets are loaded into the machine

- One solid block is loaded into the machine

- The thickness of the part

- The volume of the part

- The complexity of the part

- The number of parts in the mold

- The part falls free from the mold on its own

- The machine operator pulls the part out manually

- An ejection machine reaches into the mold and pulls out the part

- A mechanism attached to the mold pushes out the part when it opens

- Milling to improve tolerances

- Grinding to improve surface finish

- Trimming to remove excess material

- Painting to add color

Injection molding machines have many components and are available in different configurations, including a horizontal configuration and a vertical configuration. However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of the process cycle.

Injection molding machine - Overview

Injection molding machine - Overview

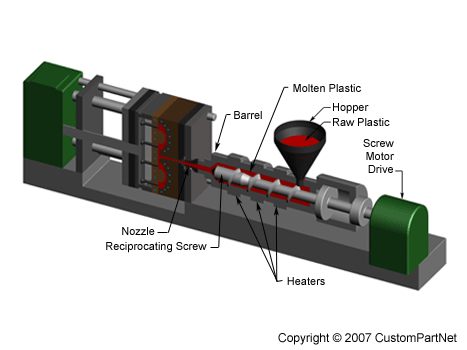

The injection unit is responsible for both heating and injecting the material into the mold. The first part of this unit is the hopper, a large container into which the raw plastic is poured. The hopper has an open bottom, which allows the material to feed into the barrel. The barrel contains the mechanism for heating and injecting the material into the mold. This mechanism is usually a ram injector or a reciprocating screw. A ram injector forces the material forward through a heated section with a ram or plunger that is usually hydraulically powered. Today, the more common technique is the use of a reciprocating screw. A reciprocating screw moves the material forward by both rotating and sliding axially, being powered by either a hydraulic or electric motor. The material enters the grooves of the screw from the hopper and is advanced towards the mold as the screw rotates. While it is advanced, the material is melted by pressure, friction, and additional heaters that surround the reciprocating screw. The molten plastic is then injected very quickly into the mold through the nozzle at the end of the barrel by the buildup of pressure and the forward action of the screw. This increasing pressure allows the material to be packed and forcibly held in the mold. Once the material has solidified inside the mold, the screw can retract and fill with more material for the next shot.

Injection molding machine - Injection unit

Injection molding machine - Injection unit

Prior to the injection of the molten plastic into the mold, the two halves of the mold must first be securely closed by the clamping unit. When the mold is attached to the injection molding machine, each half is fixed to a large plate, called a platen. The front half of the mold, called the mold cavity, is mounted to a stationary platen and aligns with the nozzle of the injection unit. The rear half of the mold, called the mold core, is mounted to a movable platen, which slides along the tie bars. The hydraulically powered clamping motor actuates clamping bars that push the moveable platen towards the stationary platen and exert sufficient force to keep the mold securely closed while the material is injected and subsequently cools. After the required cooling time, the mold is then opened by the clamping motor. An ejection system, which is attached to the rear half of the mold, is actuated by the ejector bar and pushes the solidified part out of the open cavity.

Injection molding machine - Clamping unit

Injection molding machine - Clamping unit

Machine specifications

Injection molding machines are typically

characterized by the tonnage of the

clamp force they provide. The required

clamp force is determined by the

projected area

of the parts in the mold and the pressure with which the material is

injected. Therefore, a larger part will require a larger

clamping force. Also, certain materials that require

high injection pressures may require higher tonnage

machines. The size of the part must also comply with

other machine specifications, such as

shot capacity,

clamp stroke,

minimum mold thickness, and platen

size.

Injection molded parts can vary greatly in size

and therefore require these measures to cover a very large range. As

a result, injection molding machines are designed to each

accommodate a small range of this larger spectrum of values. Sample

specifications are shown below for three different models

(Babyplast, Powerline, and Maxima) of injection molding machine

that are manufactured by Cincinnati Milacron.

| Babyplast | Powerline | Maxima | |

| Clamp force (ton) | 6.6 | 330 | 4400 |

| Shot capacity (oz.) | 0.13 - 0.50 | 8 - 34 | 413 - 1054 |

| Clamp stroke (in.) | 4.33 | 23.6 | 133.8 |

| Min. mold thickness (in.) | 1.18 | 7.9 | 31.5 |

| Platen size (in.) | 2.95 x 2.95 | 40.55 x 40.55 | 122.0 x 106.3 |

Injection molding machine

- Stationary platen, Mold cavity, Mold core

- Sprue, Runner, Gate

- Hopper, Barrel, Nozzle

- Clamping bar, Ejector box, Ejector pins

- Hopper

- Barrel

- Nozzle

- Mold

- Storing the raw plastic to be melted

- Melting the raw plastic

- Pushing the molten plastic into the mold

- Opening and closing the mold

- Opening the mold

- Closing the mold

- Applying force to keep the mold closed

- All of the above

- Moveable platen

- Stationary platen

- Mold cavity

- Clamping bar

- Providing a surface for the mold halves to be mounted in the machine

- Pushing the mold core towards the mold cavity

- Keeping the mold halves clamped together

- Guiding the mold core towards the mold cavity

- Part size

- Production quantity

- Number of parts per mold

- Material

- The shot capacity must be very high

- The clamp stroke must be very long

- The minimum mold thickness must be very thick

- The platen size must be very large

- Mold core

- Ejector bar

- Molten plastic

- Barrel

- Clamping motor drive

- Stationary platen

- Nozzle

- Hopper

- Clamping bar

- Ejection system

- Heaters

- Raw plastic

- Rear platen

- Mold cavity

- Reciprocating screw

- Molded part

- Screw motor drive

- Moveable platen

- Tie bar

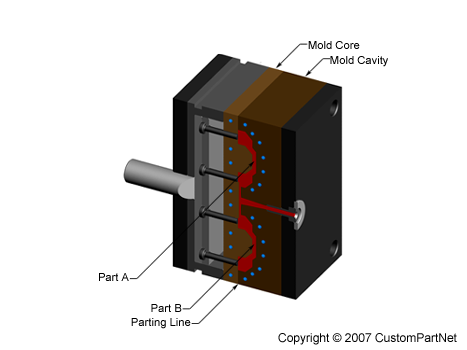

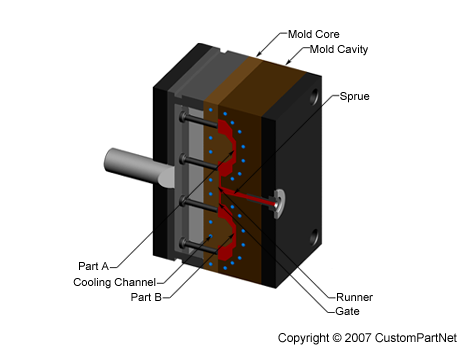

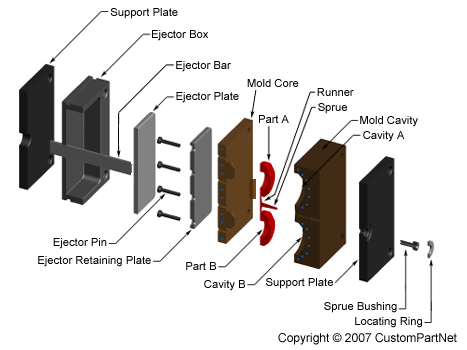

The injection molding process uses molds, typically made of steel or aluminum, as the custom tooling. The mold has many components, but can be split into two halves. Each half is attached inside the injection molding machine and the rear half is allowed to slide so that the mold can be opened and closed along the mold's parting line. The two main components of the mold are the mold core and the mold cavity. When the mold is closed, the space between the mold core and the mold cavity forms the part cavity, that will be filled with molten plastic to create the desired part. Multiple-cavity molds are sometimes used, in which the two mold halves form several identical part cavities.

Mold overview

Mold overview

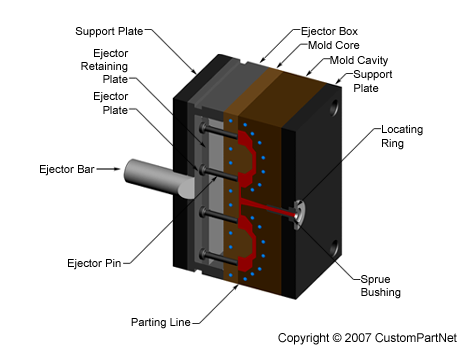

The mold core and mold cavity are each mounted to the mold base, which is then fixed to the platens inside the injection molding machine. The front half of the mold base includes a support plate, to which the mold cavity is attached, the sprue bushing, into which the material will flow from the nozzle, and a locating ring, in order to align the mold base with the nozzle. The rear half of the mold base includes the ejection system, to which the mold core is attached, and a support plate. When the clamping unit separates the mold halves, the ejector bar actuates the ejection system. The ejector bar pushes the ejector plate forward inside the ejector box, which in turn pushes the ejector pins into the molded part. The ejector pins push the solidified part out of the open mold cavity.

Mold base

Mold base

In order for the molten plastic to flow into the mold cavities, several channels are integrated into the mold design. First, the molten plastic enters the mold through the sprue. Additional channels, called runners, carry the molten plastic from the sprue to all of the cavities that must be filled. At the end of each runner, the molten plastic enters the cavity through a gate which directs the flow. The molten plastic that solidifies inside these runners is attached to the part and must be separated after the part has been ejected from the mold. However, sometimes hot runner systems are used which independently heat the channels, allowing the contained material to be melted and detached from the part. Another type of channel that is built into the mold is cooling channels. These channels allow water to flow through the mold walls, adjacent to the cavity, and cool the molten plastic.

Mold channels

Mold channels

Mold design

In addition to runners and gates,

there are many other design issues that must be

considered in the design of the molds. Firstly, the mold

must allow the molten plastic to flow easily into all of

the cavities. Equally important is the removal of the

solidified part from the mold, so a draft

angle must be applied to the mold walls.

The design of the mold must also accommodate any complex

features on the part, such as undercuts or

threads, which will require additional mold pieces. Most

of these devices slide into the part cavity through the

side of the mold, and are therefore known as slides, or

side-actions.

The most common type of side-action

is a side-core which enables an

external undercut to be molded.

Other devices enter through the end of the mold along the

parting direction,

such as internal core lifters, which can form an

internal undercut. To mold threads into the part,

an unscrewing device is needed, which can rotate

out of the mold after the threads have been formed.

Mold - Exploded view

- Mold line

- Separation line

- Parting line

- Cavity line

- Nozzle

- Sprue bushing

- Support plate

- Ejection system

- Ejector box pushes ejector plate, which pushes ejector pins, which ejects part

- Ejector bar pushes ejector box, which pushes ejector pins, which ejects part

- Ejector box pushes ejector pins, which pushes ejector plate, which ejects part

- Ejector bar pushes ejector plate, which pushes ejector pins, which ejects part

- Sprue, Nozzle, Runner, Gate, Part cavity

- Nozzle, Sprue, Runner, Gate, Part cavity

- Gate, Nozzle, Sprue, Runner, Part cavity

- Nozzle, Gate, Sprue, Runner, Part cavity

- It is always in a molten state

- It solidifies and remains in place to be melted for the next shot

- It solidifies and is ejected after the part is ejected

- It solidifies and remains attached to the ejected part

- All surfaces

- All flat surfaces

- All surfaces parallel to the parting direction

- All surfaces perpendicular to the parting direction

- 0

- 2

- 4

- 8

- Unscrewing device

- Lifter

- Side-core

- Side-action

- Mold cavity

- Locating ring

- Ejector retaining plate

- Gate

- Support plate

- Ejector pin

- Parting line

- Sprue bushing

- Ejector bar

- Sprue

- Support plate

- Molded part

- Runner

- Ejector box

- Mold core

- Ejector plate

- Cooling channel