Loading library...

Processes - Thermal Spray & PVD/CVD Coating

Thermal Spray & PVD/CVD Coating

Thermal Spray and PVD/CVD coatings are sophisticated surface engineering processes to improve wear resistance, corrosion protection, heat insulation, and surface hardness of components without altering their bulk character. They have broad applications in aerospace, automotive, electronics, biomedical, and tooling industries.

Process Cycle

- Surface conditioning (grit blasting or plasma cleaning)

- Coating material deposition by CVD, PVD, or spray

- Cooling and bonding consolidation

- Post-treatment (sealing, heat treatment, polishing)

- Inspection: microstructure, thickness, porosity, and adhesion

Equipment

- Thermal Spray Guns (Wire Arc, HVOF, Plasma)

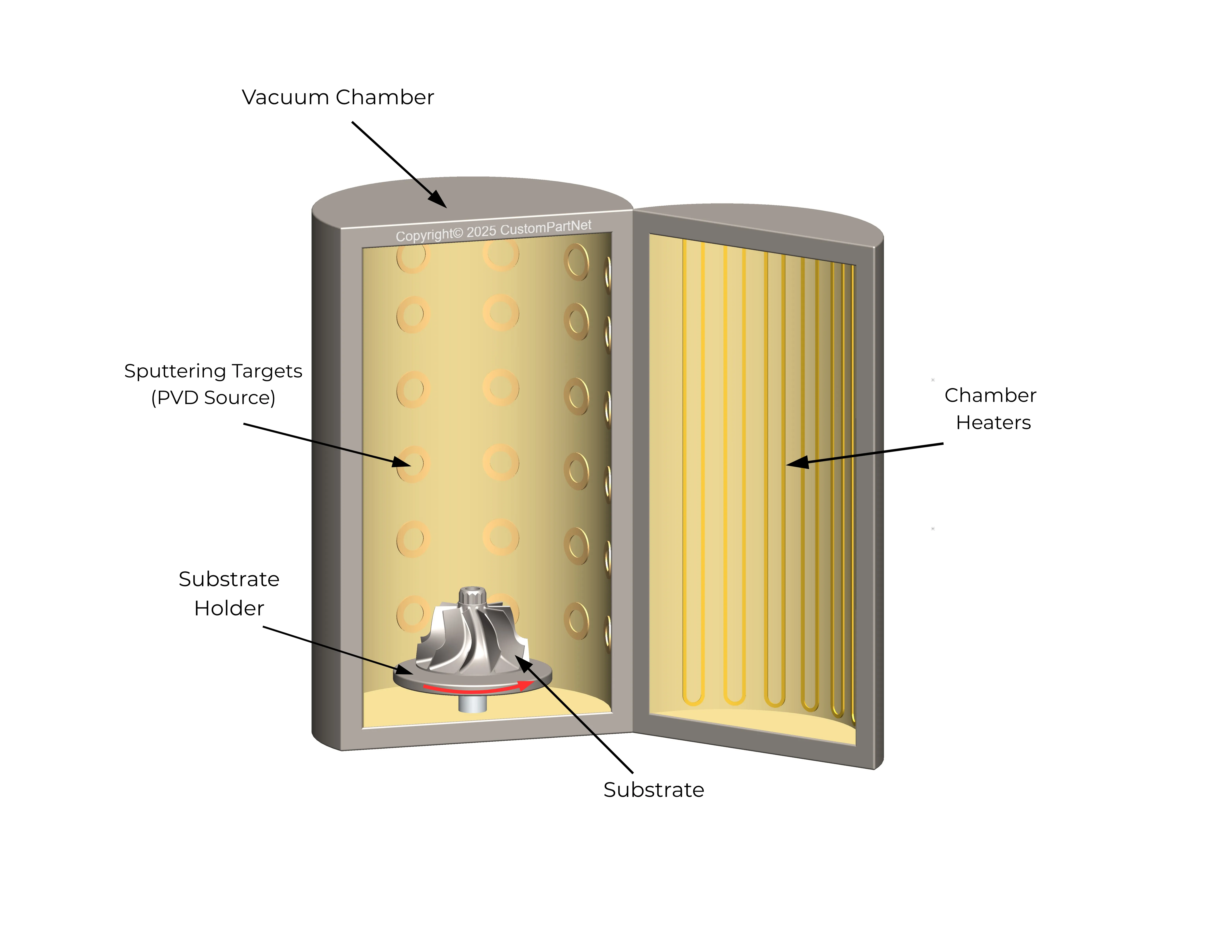

- Physical Vapor Deposition chambers (sputtering, evaporation, arc)

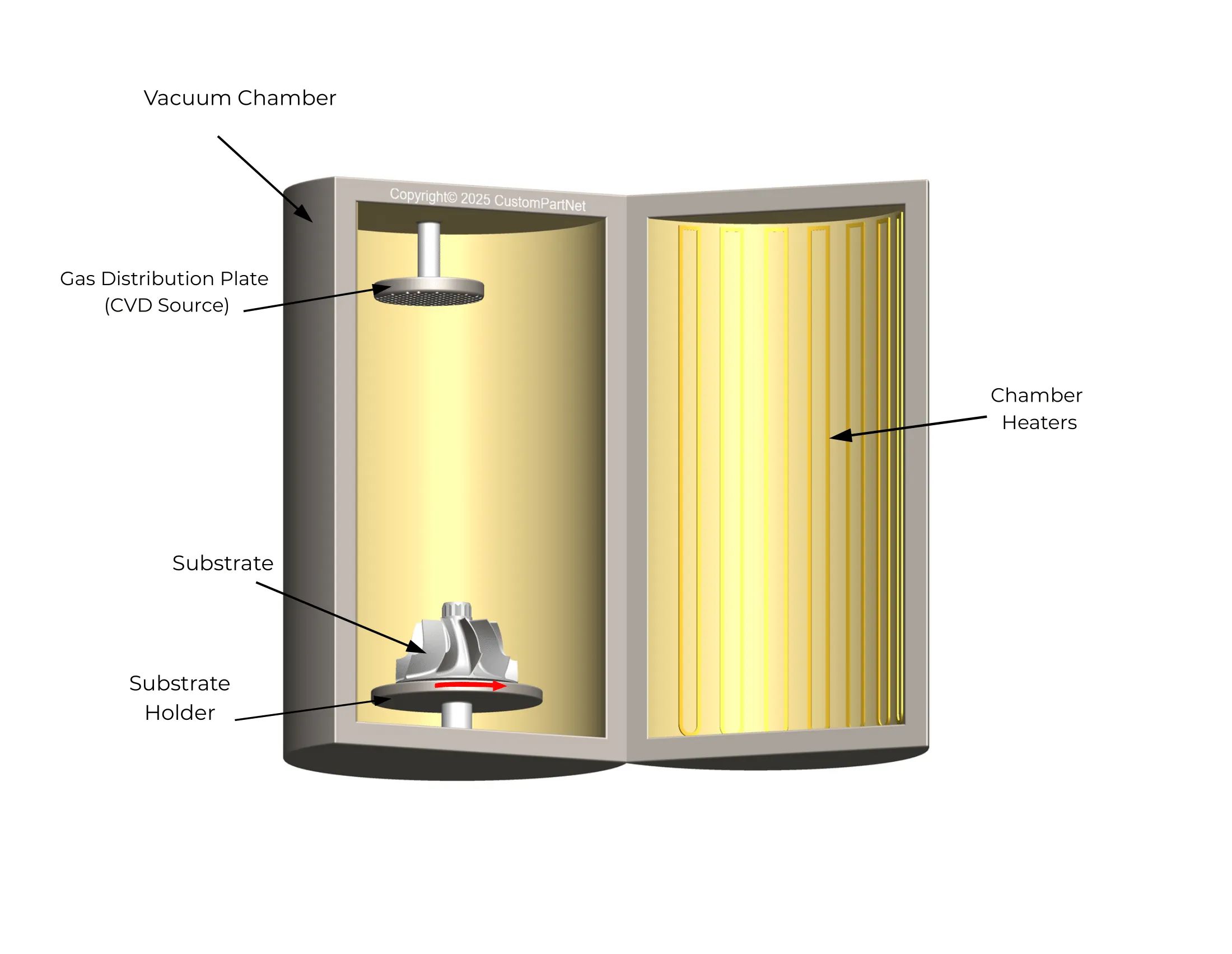

- Chemical Vapor Deposition chambers

- Substrate Handling Systems

- Masking Systems and Rotation Fixtures

- Cooling Systems

- Metrology and Inspection Tools (SEMs, profilometers)

%20with%20Labels.webp)

Tooling

Primary:

- Nozzles, plasma torches, deposition crucibles

- Vacuum fixtures, rotating stages

Secondary:

- Custom jigs for masking and positioning

- Substrate pre-heating systems

- Cooling gas nozzles

Materials

| Coating Type | Substrate Material | Functional Benefit |

|---|---|---|

| Al2O3, Cr3C2 | All metals | Thermal and wear resistance |

| TiN, TiAlN | Tool steels, HSS | Surface hardness and lubricity |

| DLC, SiC | Polymers, alloys | Low friction, chemical resistance |

Possible Defects

- Delamination or poor adhesion

- Pinholes or porosity in the coating

- Cracking due to thermal mismatch

- Non-uniform thickness due to geometry

- Residual stresses or oxidation

Design Guidelines

- Ensure line-of-sight access for deposition

- Use radii instead of sharp corners to reduce stress

- Consider substrate thermal expansion compatibility

- Design for uniform coating thickness

- Mask non-coated regions precisely

Cost Drivers

- Coating material (e.g., high-purity ceramic powders)

- Deposition method (thermal vs. PVD/CVD)

- Part geometry and masking complexity

- Number of coated surfaces

- Equipment maintenance and vacuum control

Thermal spray and PVD/CVD coatings provide precision-engineered surface solutions for wear, corrosion resistance, and functional performance. Their versatility across a broad range of materials and challenging geometries makes them a mainstay in aerospace, medical, and high-performance industrial uses. Proper process selection and design matching lead to optimum efficiency and lifespan.