Overviews |

- Processes

- Polymer Processing

- Blow Molding

- Injection Molding

- Metal Injection Molding

- Thermoforming

- Metal Casting

- Centrifugal Casting

- Die Casting

- Investment Casting

- Permanent Mold

- Sand Casting

- Shell Mold Casting

- Machining

- Milling

- Turning

- Hole-making

- Drill Size Chart

- Tap Size Chart

- Sheet Metal Fabrication

- Forming

- Cutting with shear

- Cutting without shear

- Gauge Size Chart

- Additive Fabrication

- SLA

- FDM

- SLS

- DMLS

- 3D Printing

- Inkjet Printing

- Jetted Photopolymer

- LOM

- Materials

- Metals

- Plastics

- Case Studies

- Cost Analysis

- Part Redesign

- Product Development

- Resources

- Curriculum Resources

- Glossary

From Concept to Production using CustomPartNet

With services including CAD modeling, design review, and rapid prototyping

Introduction

Many users of CustomPartNet are not professional engineers, but rather students, inventors, or hobbyists that wish to design a new product. One such user, named Dick Gregg, found the CustomPartNet website and began reading the process overviews and design guidelines to learn how to properly design a part to be injection molded. However, like many amateur inventors, Dick lacked the technical expertise to implement what he had learned into creating professional CAD models and drawings. Such drawings would be needed for the prototyping and eventual production of his product. So, Dick decided to contact the staff at CustomPartNet for assistance.

The Product

Dick described his product, the "Bungee Block", as a "bungee cord tie-down device that utilizes a patent pending locking wheel system". The device was designed as a 3-piece assembly, through which a bungee cord would be fed, plus a separate cylindrical piece for the end of the cord. Dick wanted the Bungee Block to be available in 4 different sizes, to accommodate 1/8", 3/16", 1/4", and 3/8" diameter bungee cords. Therefore, a total of 16 separate components needed to be designed. Having some machining experience, Dick created a conceptual prototype from wood for each of the product sizes.

|

| Wood prototypes of design concept for 1/8", 3/16", 1/4", and 3/8" Bungee Blocks |

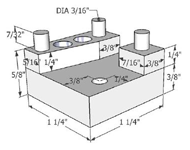

CAD Modeling

As mentioned above, Dick needed assistance in creating the CAD models and drawings to illustrate his design to manufacturers. With the use of some basic CAD software, he was able to model a rough version of his design to convey the concept and basic dimensions. From these drawings, CustomPartNet was asked to model all 16 components (4 for each of the 4 product sizes) plus the 4 assemblies of these components. Additionally, some features that Dick could not model, such as rounded corners and more complex surfaces, had to be added to the design. During the modeling process, minor corrections were also made to the dimensioning of the parts in case of a contradiction, omission, or error. After 48 hours, the CAD modeling work was completed and included the 3D models, 2D drawings, and rendered images for all parts and assemblies.

|

| CAD models of design concept (3 components for 1/4" Bungee Block) |

|

| CustomPartNet CAD models of initial design (4 components and assembly of 1/4" Bungee Block) |

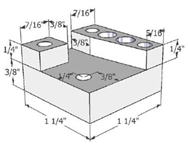

Design Review and Redesign

With the CAD modeling of the initial design complete, Dick began to investigate the

manufacturability and cost of his product. He decided that the Bungee Block should be made from a

durable plastic and wanted an initial run of 1000 products that could easily be scaled up to high

volume production. From reading the CustomPartNet process overviews, Dick determined that the product

should be injection molded and would require a redesign using proper DFM (Design for Manufacturing)

design rules. He decided to ask CustomPartNet to perform a design review of all 16 parts and complete

the CAD redesign, implementing all approved changes.

The initial stage of the design review was to propose possible design alternatives. Before addressing

the design issues to improve manufacturability and part quality, CustomPartNet offered suggestions

that may improve other areas. For example, two design concepts were modeled to demonstrate a new method

of assembly and a slimmer exterior. Ultimately, Dick preferred to remain closer to his original concept.

|

| Possible design alternatives |

The design review process continued with making any changes that would improve the manufacturability, assembly, cost, and end-use of the product. The primary source of much of the redesign was the presence of thick material sections on many of the parts. Wall thickness that is too great and non-uniform will not only increase the time and cost of the injection molding process, but is likely to cause several part defects. In order to reduce the wall thickness of each part and make it more uniform throughout, the press-fit assembly features and wheel axle features had to be redesigned. The new press-fit assembly was designed to also ensure a more secure fit and the new wheel axle design allowed for a simpler and less expensive mold. Following these substantial changes, more minor alternations were made including the addition of rounded corners, draft angles, and ribs for structural support. Updated CAD models, drawings, and images were then created.

|

| CustomPartNet CAD models of redesign (4 components and assembly of 1/4" Bungee Block) |

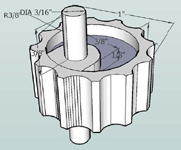

Prototyping

After reviewing the redesigned parts, Dick was pleased with all of the changes but wanted to

see how this new design would look and feel once manufactured. After all, the only design he had held and

tested was his early conceptual model made from wood. CustomPartNet recommended the quick fabrication of a

few prototypes using FDM (Fused Deposition Modeling), a rapid prototyping technology that build parts directly

from the CAD models. These prototypes would allow Dick a quick and inexpensive way to test the form and fit of

the components. Any desired changes to the design could be quickly implemented and new prototypes fabricated.

The first round of prototypes were fabricated and shipped to Dick in a matter of days. He was then able to not

only see and feel his invention, but actually attach the bungee cords and test the functionality. The redesigned

Bungee Blocks were a success. An added benefit of the prototypes was that Dick was able to identify a few areas

for improvement that could only be noticed by handling a physical model of the product. At his request,

CustomPartNet made some modifications to the design and created new CAD models and drawings. The changes included

the following:

- Slight increase in wall thickness for a more solid feel

- Increase in diameter of assembly pins for added strength

- Adjustment of wheel position for easier movement of the bungee cords

- Decrease in clearances of the wheel axle to reduce wobbling

The new prototypes solved the remaining issues and Dick was now ready to proceed with the injection molding of his product.

|

| FDM prototypes of final design for 1/8", 3/16", 1/4", and 3/8" Bungee Blocks |

Final Product

CustomPartNet recently spoke to Dick to follow up on the development of the Bungee Block. He informed us that following the successful modeling and prototyping of the parts, he found a supplier to manufacture the parts through injection molding. The Bungee Block turned out exactly as he had hoped and will soon be available in stores.

|

| Injection molded final product |

- Dick Gregg