- Processes

- Polymer Processing

- Blow Molding

- Injection Molding

- Metal Injection Molding

- Thermoforming

- Metal Casting

- Centrifugal Casting

- Die Casting

- Investment Casting

- Permanent Mold

- Sand Casting

- Shell Mold Casting

- Machining

- Milling

- Turning

- Hole-making

- Drill Size Chart

- Tap Size Chart

- Sheet Metal Fabrication

- Forming

- Cutting with shear

- Cutting without shear

- Gauge Size Chart

- Additive Fabrication

- SLA

- FDM

- SLS

- DMLS

- 3D Printing

- Inkjet Printing

- Jetted Photopolymer

- LOM

- Materials

- Metals

- Plastics

- Case Studies

- Cost Analysis

- Part Redesign

- Product Development

- Resources

- Curriculum Resources

- Glossary

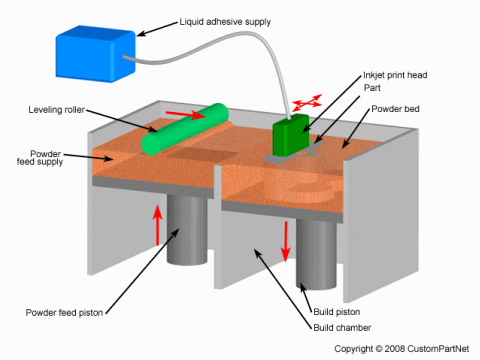

Three Dimensional Printing (3DP)

technology was developed at the Massachusetts Institute

of Technology and licensed to several corporations. The

process is similar to the Selective Laser Sintering (SLS)

process, but instead of using a laser to sinter the

material, an ink-jet printing head deposits a liquid

adhesive that binds the material. Material options,

which include metal or ceramic powders, are somewhat

limited but are inexpensive relative to other additive

processes. 3D Printing offers the advantage of fast

build speeds, typically 2-4 layers per minute. However,

the accuracy, surface finish, and part strength are not

quite as good as some other additive processes. 3D

Printing is typically used for the rapid prototyping of

conceptual models (limited functional testing is

possible).

The 3D printing process begins with

the powder supply being raised by a piston and a

leveling roller distributing a thin layer of powder to

the top of the build chamber. A multi-channel ink-jet

print head then deposits a liquid adhesive to targeted

regions of the powder bed. These regions of powder are

bonded together by the adhesive and form one layer of

the part. The remaining free standing powder supports

the part during the build. After a layer is built, the

build platform is lowered and a new layer of powder

added, leveled, and the printing repeated. After the

part is completed, the loose supporting powder can be

brushed away and the part removed. 3D printed parts are

typically infiltrated with a sealant to improve strength

and surface finish.

Three Dimensional Printing (3DP)

Capabilities

Disclaimer: All process specifications reflect the approximate range of a process's capabilities and should be viewed only as a guide. Actual capabilities are dependent upon the manufacturer, equipment, material, and part requirements.

Return to top |