- Processes

- Polymer Processing

- Blow Molding

- Injection Molding

- Metal Injection Molding

- Thermoforming

- Metal Casting

- Centrifugal Casting

- Die Casting

- Investment Casting

- Permanent Mold

- Sand Casting

- Shell Mold Casting

- Machining

- Milling

- Turning

- Hole-making

- Drill Size Chart

- Tap Size Chart

- Sheet Metal Fabrication

- Forming

- Cutting with shear

- Cutting without shear

- Gauge Size Chart

- Additive Fabrication

- SLA

- FDM

- SLS

- DMLS

- 3D Printing

- Inkjet Printing

- Jetted Photopolymer

- LOM

- Materials

- Metals

- Plastics

- Case Studies

- Cost Analysis

- Part Redesign

- Product Development

- Resources

- Curriculum Resources

- Glossary

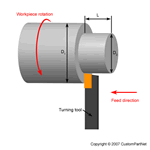

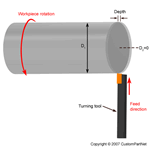

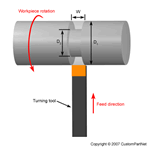

Turning is a form of machining, a

material removal process, which is used to create

rotational parts by cutting away unwanted material. The

turning process requires a turning machine or lathe,

workpiece,

fixture, and cutting tool. The workpiece is a

piece of pre-shaped material that is secured to the

fixture, which itself is attached to the turning

machine, and allowed to rotate at high speeds. The

cutter is typically a single-point cutting tool that is

also secured in the machine, although some operations

make use of multi-point tools. The cutting tool feeds

into the rotating workpiece and cuts away material in

the form of small chips to create the desired shape.

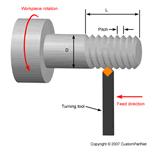

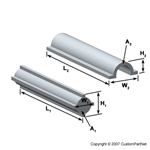

Turning is used to produce

rotational, typically axi-symmetric, parts that have

many features, such as holes, grooves, threads, tapers,

various diameter steps, and even contoured surfaces.

Parts that are fabricated completely through turning

often include components that are used in limited

quantities, perhaps for prototypes, such as custom

designed shafts and fasteners. Turning is also commonly

used as a secondary process to add or refine features on

parts that were manufactured using a different process.

Due to the high tolerances and surface finishes that

turning can offer, it is ideal for adding precision

rotational features to a part whose basic shape has

already been formed.

Capabilities

Disclaimer: All process specifications reflect the approximate range of a process's capabilities and should be viewed only as a guide. Actual capabilities are dependent upon the manufacturer, equipment, material, and part requirements.

Return to top | ||||||||||||||||||||||||||||||||||||||

Process Cycle

The time required to produce a given quantity of parts includes the initial setup time and the cycle time for each part. The setup time is composed of the time to setup the turning machine, plan the tool movements (whether performed manually or by machine), and install the fixture device into the turning machine. The cycle time can be divided into the following four times:

Load/Unload time

- The time required to load the workpiece into the turning machine and secure it to the fixture, as well as the time to unload the finished part. The load time can depend on the size, weight, and complexity of the workpiece, as well as the type of fixture.Cut time

- The time required for the cutting tool to make all the necessary cuts in the workpiece for each operation. The cut time for any given operation is calculated by dividing the total cut length for that operation by the feed rate, which is the speed of the tool relative to the workpiece.Idle time

- Also referred to as non-productive time, this is the time required for any tasks that occur during the process cycle that do not engage the workpiece and therefore remove material. This idle time includes the tool approaching and retracting from the workpiece, tool movements between features, adjusting machine settings, and changing tools.Tool replacement time

- The time required to replace a tool that has exceeded its lifetime and therefore become to worn to cut effectively. This time is typically not performed in every cycle, but rather only after the lifetime of the tool has been reached. In determining the cycle time, the tool replacement time is adjusted for the production of a single part by multiplying by the frequency of a tool replacement, which is the cut time divided by the tool lifetime.

Following the turning process

cycle, there is no post processing that is required.

However, secondary processes may be used to improve the

surface finish of the part if it is required. The scrap

material, in the form of small material chips cut from

the workpiece, is propelled away from the workpiece by

the motion of the cutting tool and the spraying of

lubricant. Therefore, no process cycle step is required

to remove the scrap material, which can be collected and

discarded after the production.

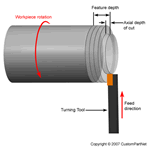

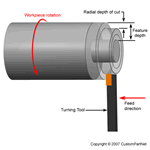

Cutting parameters

In turning, the speed and motion of the cutting tool is

specified through several parameters. These parameters

are selected for each operation based upon the workpiece

material, tool material, tool size, and more.

- Cutting feed - The distance that the cutting tool or workpiece advances during one revolution of the spindle, measured in inches per revolution (IPR). In some operations the tool feeds into the workpiece and in others the workpiece feeds into the tool. For a multi-point tool, the cutting feed is also equal to the feed per tooth, measured in inches per tooth (IPT), multiplied by the number of teeth on the cutting tool.

- Cutting speed - The speed of the workpiece surface relative to the edge of the cutting tool during a cut, measured in surface feet per minute (SFM).

- Spindle speed - The rotational speed of the spindle and the workpiece in revolutions per minute (RPM). The spindle speed is equal to the cutting speed divided by the circumference of the workpiece where the cut is being made. In order to maintain a constant cutting speed, the spindle speed must vary based on the diameter of the cut. If the spindle speed is held constant, then the cutting speed will vary.

- Feed rate - The speed of the cutting tool's movement relative to the workpiece as the tool makes a cut. The feed rate is measured in inches per minute (IPM) and is the product of the cutting feed (IPR) and the spindle speed (RPM).

- Axial depth of cut - The depth of the tool along the axis of the workpiece as it makes a cut, as in a facing operation. A large axial depth of cut will require a low feed rate, or else it will result in a high load on the tool and reduce the tool life. Therefore, a feature is typically machined in several passes as the tool moves to the specified axial depth of cut for each pass.

- Radial depth of cut - The depth of the tool along the radius of the workpiece as it makes a cut, as in a turning or boring operation. A large radial depth of cut will require a low feed rate, or else it will result in a high load on the tool and reduce the tool life. Therefore, a feature is often machined in several steps as the tool moves over at the radial depth of cut.

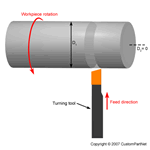

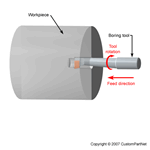

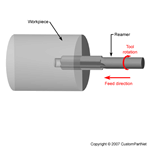

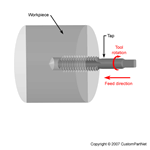

Operations

During the process cycle, a variety of operations may be performed to the workpiece to yield the desired part shape. These operations may be classified as external or internal. External operations modify the outer diameter of the workpiece, while internal operations modify the inner diameter. The following operations are each defined by the type of cutter used and the path of that cutter to remove material from the workpiece.

- External operations

- Internal operations

Return to top

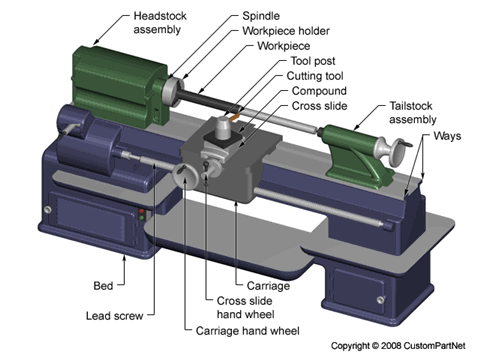

Equipment

Turning machines, typically referred to as lathes, can be found in a variety of sizes and designs. While most lathes are horizontal turning machines, vertical machines are sometimes used, typically for large diameter workpieces. Turning machines can also be classified by the type of control that is offered. A manual lathe requires the operator to control the motion of the cutting tool during the turning operation. Turning machines are also able to be computer controlled, in which case they are referred to as a computer numerical control (CNC) lathe. CNC lathes rotate the workpiece and move the cutting tool based on commands that are preprogrammed and offer very high precision. In this variety of turning machines, the main components that enable the workpiece to be rotated and the cutting tool to be fed into the workpiece remain the same. These components include the following:

Bed

- The bed of the turning machine is simply a large base that sits on the ground or a table and supports the other components of the machine.Headstock assembly

- The headstock assembly is the front section of the machine that is attached to the bed. This assembly contains the motor and drive system which powers the spindle. The spindle supports and rotates the workpiece, which is secured in a workpiece holder or fixture, such as a chuck or collet.Tailstock assembly

- The tailstock assembly is the rear section of the machine that is attached to the bed. The purpose of this assembly is to support the other end of the workpiece and allow it to rotate, as it's driven by the spindle. For some turning operations, the workpiece is not supported by the tailstock so that material can be removed from the end.Carriage

- The carriage is a platform that slides alongside the workpiece, allowing the cutting tool to cut away material as it moves. The carriage rests on tracks that lay on the bed, called "ways", and is advanced by a lead screw powered by a motor or hand wheel.Cross slide

- The cross slide is attached to the top of the carriage and allows the tool to move towards or away from the workpiece, changing the depth of cut. As with the carriage, the cross slide is powered by a motor or hand wheel.Compound

- The compound is attached on top of the cross slide and supports the cutting tool. The cutting tool is secured in a tool post which is fixed to the compound. The compound can rotate to alter the angle of the cutting tool relative to the workpiece.Turret

- Some machines include a turret, which can hold multiple cutting tools and rotates the required tool into position to cut the workpiece. The turret also moves along the workpiece, feeding the cutting tool into the material. While most cutting tools are stationary in the turret, live tooling can also be used. Live tooling refers to powered tools, such as mills, drills, reamers, and taps, which rotate and cut the workpiece.

Return to top

Tooling

The tooling that is required for turning is typically a sharp single-point cutting tool that is either a single piece of metal or a long rectangular tool shank with a sharp insert attached to the end. These inserts can vary in size and shape, but are typically a square, triangle, or diamond shaped piece. These cutting tools are inserted into the turret or a tool holder and fed into the rotating workpiece to cut away material. These single point cutting tools are available in a variety of shapes that allow for the formation of different features. Some common types of tools are as follows:

- Style A - 0 degree lead-angle turning tools

- Style B - 15 degree lead-angle turning tools

- Style C - 0 degree square nose tools

- Style D - 80 degree included angle pointed-nose tools

- Style E - 60 degree included angle pointed-nose tools

- Cutoff tools

- Form tools

The above tools are often specified

as being right or left handed, which indicates in which

direction they move along the workpiece while making a

cut.

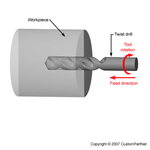

As described in the previous

section, live tooling can also be used for turning,

which includes the use of mills, drills, reamers, and

taps. These are cylindrical multi-point cutting tools

that have sharp teeth spaced around the exterior. The

spaces between the teeth are called flutes and allow the

material chips to move away from the workpiece. The

teeth may be straight along the side of the cutter, but

are more commonly arranged in a helix. The helix angle

reduces the load on the teeth by distributing the

forces. Also, the number of teeth on a cutter varies. A

larger number of teeth will provide a better surface

finish. The cutter teeth cover only a portion of the

tool, while the remaining length is a smooth surface,

called the shank. The shank is the section of the cutter

that is secured inside the tool holder.

All cutting tools that are used in

turning can be found in a variety of materials, which

will determine the tool's properties and the workpiece

materials for which it is best suited. These properties

include the tool's hardness, toughness, and resistance

to wear. The most common tool materials that are used

include the following:

- High-speed steel (HSS)

- Carbide

- Carbon steel

- Cobalt high speed steel

The material of the tool is chosen based upon a number of factors, including the material of the workpiece, cost, and tool life. Tool life is an important characteristic that is considered when selecting a tool, as it greatly affects the manufacturing costs. A short tool life will not only require additional tools to be purchased, but will also require time to change the tool each time it becomes too worn.

Return to top

Materials

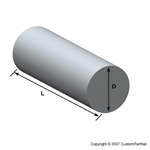

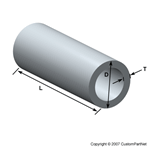

In turning, the raw form of the material is a piece of stock from which the workpieces are cut. This stock is available in a variety of shapes such as solid cylindrical bars and hollow tubes. Custom extrusions or existing parts such as castings or forgings are also sometimes used.

Turning can be performed on a variety of materials, including most metals and plastics. Common materials that are used in turning include the following:

- Aluminum

- Brass

- Magnesium

- Nickel

- Steel

- Thermoset plastics

- Titanium

- Zinc

When selecting a material, several factors must be considered, including the cost, strength, resistance to wear, and machinability. The machinability of a material is difficult to quantify, but can be said to posses the following characteristics:

- Results in a good surface finish

- Promotes long tool life

- Requires low force and power to turn

- Provides easy collection of chips

Return to top

Possible Defects

Most defects in turning are inaccuracies in a feature's dimensions or surface roughness. There are several possible causes for these defects, including the following:

Incorrect cutting parameters

- If the cutting parameters such as the feed rate, spindle speed, or depth of cut are too high, the surface of the workpiece will be rougher than desired and may contain scratch marks or even burn marks. Also, a large depth of cut may result in vibration of the tool and cause inaccuracies in the cut.Dull cutting tool

- As a tool is used, the sharp edge will wear down and become dull. A dull tool is less capable of making precision cuts.Unsecured workpiece

- If the workpiece is not securely clamped in the fixture, the friction of turning may cause it to shift and alter the desired cuts.

Return to top

Design Rules

- Select a material that minimizes overall cost. An inexpensive workpiece may result in longer cut times and more tool wear, increasing the total cost

- Minimize the amount of turning that is required by pre-cutting the workpiece close to the desired size and shape

- Select the size of the workpiece such that a large enough surface exists for the workpiece to be securely clamped. Also, the clamped surface should allow clearance between the tool and the fixture for any cuts

Features

- Minimize the number of setups that are required by designing all features to be accessible from one setup

- Design features, such as holes and threads, to require tools of standard sizes

- Minimize the number of tools that are required

- Ensure that the depth of any feature is less than the tool length and therefore will avoid the tool holder contacting the workpiece

- Lower requirements for tolerance and surface roughness, if possible, in order to reduce costs

- Avoid undercuts

Return to top

Cost Drivers

The material cost is determined by the quantity of material stock that is required and the unit price of that stock. The amount of stock is determined by the workpiece size, stock size, method of cutting the stock, and the production quantity. The unit price of the material stock is affected by the material and the workpiece shape. Also, any cost attributed to cutting the workpieces from the stock also contributes to the total material cost.

Production cost

The production cost is a result of the total production time and the hourly rate. The production time includes the setup time, load time, cut time, idle time, and tool replacement time. Decreasing any of these time components will reduce cost. The setup time and load time are dependent upon the skill of the operator. The cut time, however, is dependent upon many factors that affect the cut length and feed rate. The cut length can be shortened by optimizing the number of operations that are required and reducing the feature size if possible. The feed rate is affected by the operation type, workpiece material, tool material, tool size, and various cutting parameters such as the radial depth of cut. Lastly, the tool replacement time is a direct result of the number of tool replacements which is discussed regarding the tooling cost.

Tooling cost

The tooling cost for machining is determined by the total number of cutting tools required and the unit price for each tool. The quantity of tools depends upon the number of unique tools required by the various operations to be performed and the amount of wear that each of those tools experience. If the tool wear exceeds the lifetime of a tool, then a replacement tool must be purchased. The lifetime of a tool is dependant upon the tool material, cutting parameters such as cutting speed, and the total cut time. The unit price of a tool is affected by the tool type, size, and material.

Return to top