- Processes

- Polymer Processing

- Blow Molding

- Injection Molding

- Metal Injection Molding

- Thermoforming

- Metal Casting

- Centrifugal Casting

- Die Casting

- Investment Casting

- Permanent Mold

- Sand Casting

- Shell Mold Casting

- Machining

- Milling

- Turning

- Hole-making

- Drill Size Chart

- Tap Size Chart

- Sheet Metal Fabrication

- Forming

- Cutting with shear

- Cutting without shear

- Gauge Size Chart

- Additive Fabrication

- SLA

- FDM

- SLS

- DMLS

- 3D Printing

- Inkjet Printing

- Jetted Photopolymer

- LOM

- Materials

- Metals

- Plastics

- Case Studies

- Cost Analysis

- Part Redesign

- Product Development

- Resources

- Curriculum Resources

- Glossary

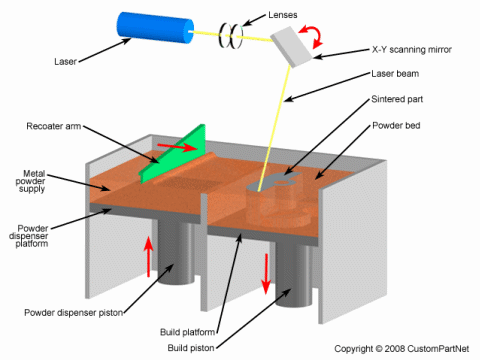

Direct Metal Laser Sintering (DMLS)

was developed jointly by Rapid Product Innovations (RPI)

and EOS GmbH, starting in 1994, as the first commercial

rapid prototyping method to produce metal parts in a

single process. With DMLS, metal powder (20 micron

diameter), free of binder or fluxing agent, is

completely melted by the scanning of a high power laser

beam to build the part with properties of the original

material. Eliminating the polymer binder avoids the

burn-off and infiltration steps, and produces a 95%

dense steel part compared to roughly 70% density with

Selective Laser Sintering (SLS). An additional benefit

of the DMLS process compared to SLS is higher detail

resolution due to the use of thinner layers, enabled by

a smaller powder diameter. This capability allows for

more intricate part shapes. Material options that are

currently offered include alloy steel, stainless steel,

tool steel, aluminum, bronze, cobalt-chrome, and

titanium. In addition to functional prototypes, DMLS is

often used to produce rapid tooling, medical implants,

and aerospace parts for high heat applications.

The DMLS process can be performed

by two different methods, powder deposition and powder

bed, which differ in the way each layer of powder is

applied. In the powder deposition method, the metal

powder is contained in a hopper that melts the powder

and deposits a thin layer onto the build platform. In

the powder bed method (shown below), the powder

dispenser piston raises the powder supply and then a

recoater arm distributes a layer of powder onto the

powder bed. A laser then sinters the layer of powder

metal. In both methods, after a layer is built the build

piston lowers the build platform and the next layer of

powder is applied. The powder deposition method offers

the advantage of using more than one material, each in

its own hopper. The powder bed method is limited to only one

material but offers faster build speeds.

Direct Metal Laser Sintering (DMLS)

Capabilities

Disclaimer: All process specifications reflect the approximate range of a process's capabilities and should be viewed only as a guide. Actual capabilities are dependent upon the manufacturer, equipment, material, and part requirements.

Return to top |