- Processes

- Polymer Processing

- Blow Molding

- Injection Molding

- Metal Injection Molding

- Thermoforming

- Metal Casting

- Centrifugal Casting

- Die Casting

- Investment Casting

- Permanent Mold

- Sand Casting

- Shell Mold Casting

- Machining

- Milling

- Turning

- Hole-making

- Drill Size Chart

- Tap Size Chart

- Sheet Metal Fabrication

- Forming

- Cutting with shear

- Cutting without shear

- Gauge Size Chart

- Additive Fabrication

- SLA

- FDM

- SLS

- DMLS

- 3D Printing

- Inkjet Printing

- Jetted Photopolymer

- LOM

- Materials

- Metals

- Plastics

- Case Studies

- Cost Analysis

- Part Redesign

- Product Development

- Resources

- Curriculum Resources

- Glossary

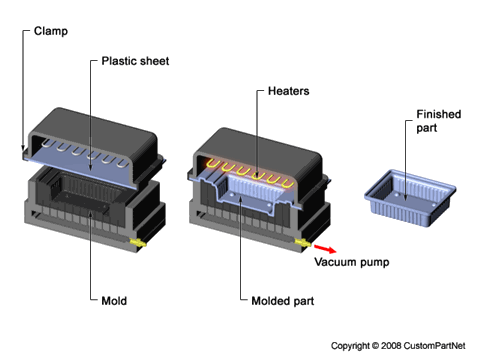

Thermoforming describes the process

of heating a thermoplastic sheet to its softening point,

stretching it over or into a single-sided mold, and

holding it in place while it cools and solidifies into

the desired shape. The thermoplastic sheet is clamped into

a holding device and heated by an oven using either convection

or radiant heat until it is softened. The sheet is then held

horizontally over a mold and pressed into or stretched over

the mold using vacuum pressure, air pressure, or mechanical

force. The softened sheet conforms to the shape of the mold

and is held in place until it cools. The excess material is

then trimmed away and the formed part is released. Excess

material can be reground, mixed with unused plastic, and

reformed into thermoplastic sheets.

Thermoforming is commonly used for food packaging, but has many

applications from plastic toys to aircraft windscreens to

cafeteria trays. Thin-gauge (less than 0.060 inches) sheets are

mostly used for rigid or disposable packaging, while thick-gauge

(greater than 0.120 inches) sheets are typically used for

cosmetic permanent surfaces on automobiles, shower enclosures,

and electronic equipment. A variety of thermoplastic materials

can be used in this process, including the following:

- Acrylic (PMMA)

- Acrylonitrile Butadiene Styrene (ABS)

- Cellulose Acetate

- Low Density Polyethylene (LDPE)

- High Density Polyethylene (HDPE)

- Polypropylene (PP)

- Polystyrene (PS)

- Polyvinyl Chloride (PVC)

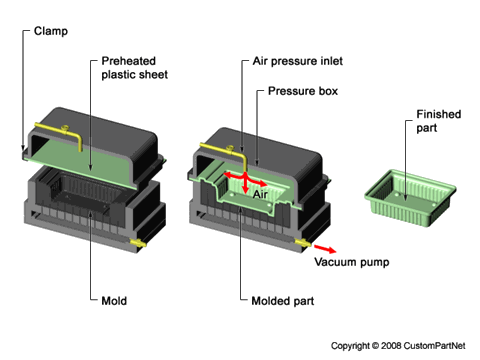

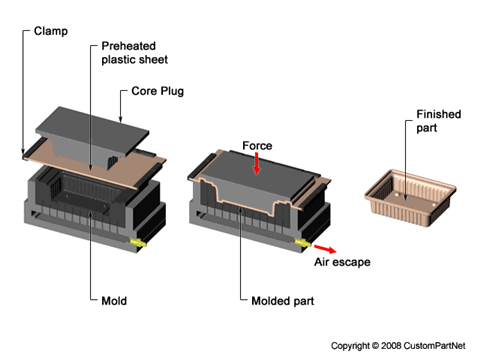

As mentioned above, there are different methods of forcing the thermoplastic sheet to conform to the mold. These types of thermoforming include the following:

-

Vacuum forming - A vacuum is formed between the mold cavity and the thermoplastic sheet.

The vacuum pressure (typically 14 psi) forces the sheet to conform to the mold and form the part

shape.

-

Pressure forming - In addition to utilizing a vacuum underneath the sheet, air pressure

(typically 50 psi, but up to 100 psi) is applied on the back side of the sheet to help force it

onto the mold. This additional force allows the forming of thicker sheets and creating finer

details, textures, undercuts, and sharp corners.

-

Mechanical forming - The thermoplastic sheet is mechanically forced into or around the mold

by direct contact. Typically, a core plug will push the sheet into the mold cavity and force it

into the desired shape.

Return to top

Capabilities

Disclaimer: All process specifications reflect the approximate range of a process's capabilities and should be viewed only as a guide. Actual capabilities are dependent upon the manufacturer, equipment, material, and part requirements.

Return to top | ||||||||||||||||||||||||||||||||||||||