Warping

The permanent bending of a part that occurs when certain section of the part shrink faster than others, as result of a non-uniform cooling rate.

The permanent bending of a part that occurs when certain section of the part shrink faster than others, as result of a non-uniform cooling rate.

The space between adjacent blanks or parts that are to be cut from a piece of sheet stock. When all parts are cut, this web of material remains attached to the sheet border and is scrap material. The web width is used in determining how many parts a single piece of sheet stock will yield.

|

Sheet stock (Rectangular blanks) |

Sheet stock (Round blanks) |

Smooth, cylindrical parts that rotate. (Includes: bearings, cams, casters, disks, pulleys, rings, rollers, tires, etc)

Wipe bending, also called edge bending, is a sheet metal bending method in which a sheet is held between a wipe die and pressure pad, and a punch presses against the edge of the sheet. The sheet will bend against the radius of the edge of the wipe die.

|

Wipe bending |

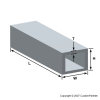

A piece of material that is secured in a fixture and machined into the final part. The workpiece is often cut from a larger piece of stock material and can be a sheet (blank), a standard extruded shape (solid bar, hollow tube, or shaped beam), a custom extrusion, or any prefabricated part such as a casting or forging. Each workpiece shape has certain dimensions that are used in planning the machining operations.

Flat sheet |

Round bar |

Rectangular bar |

Hexagonal bar |

Round tube |

Rectangular tube |

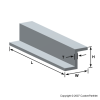

I-beam |

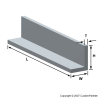

L-beam |

T-beam |

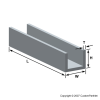

U-beam |

Z-beam |

Custom extrusions |

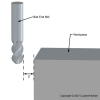

The safe distance away from the workpiece at which the cutting tool can switch from the cutting feed rate to a rapid travel rate. This distance traveled before engaging the workpiece, as well as exiting from the workpiece, is included in the cut length.

Side approach |

Top approach |

The time required to load the workpiece into the machine and secure it to the fixture. The load time can depend on the size, weight, and complexity of the workpiece, as well as the type of fixture.